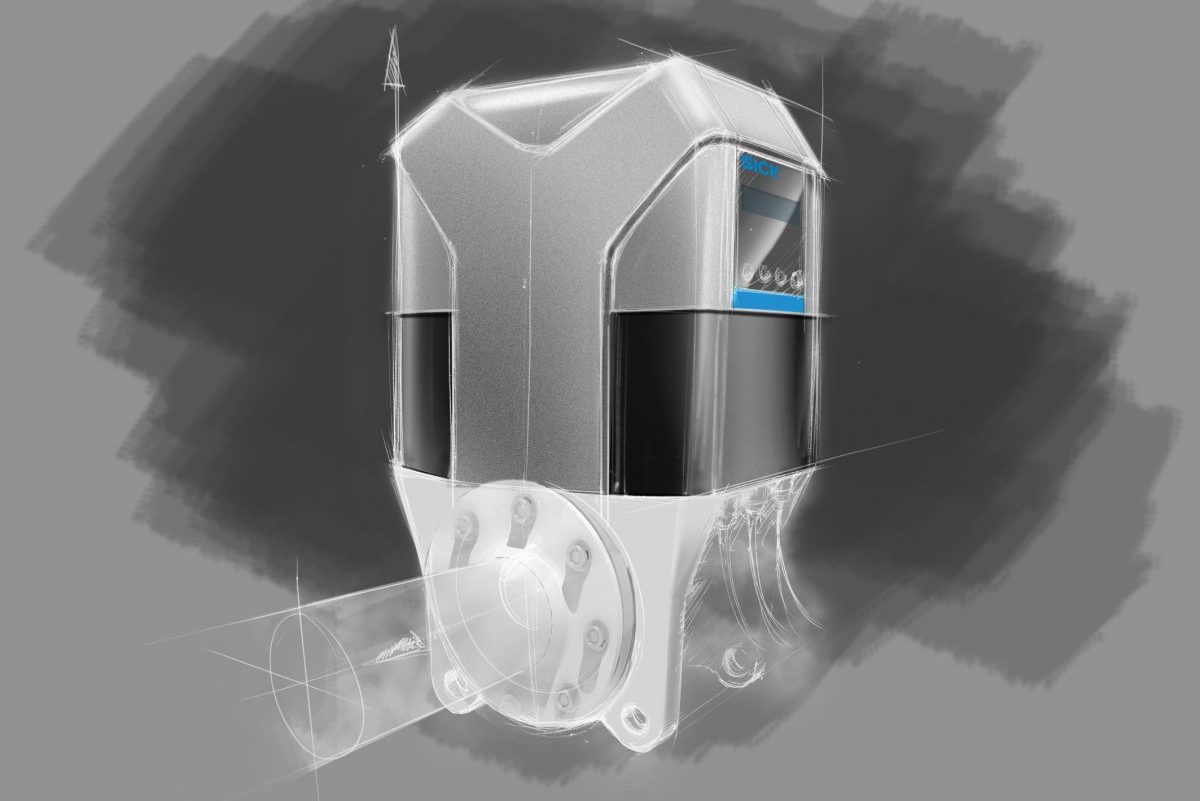

About us

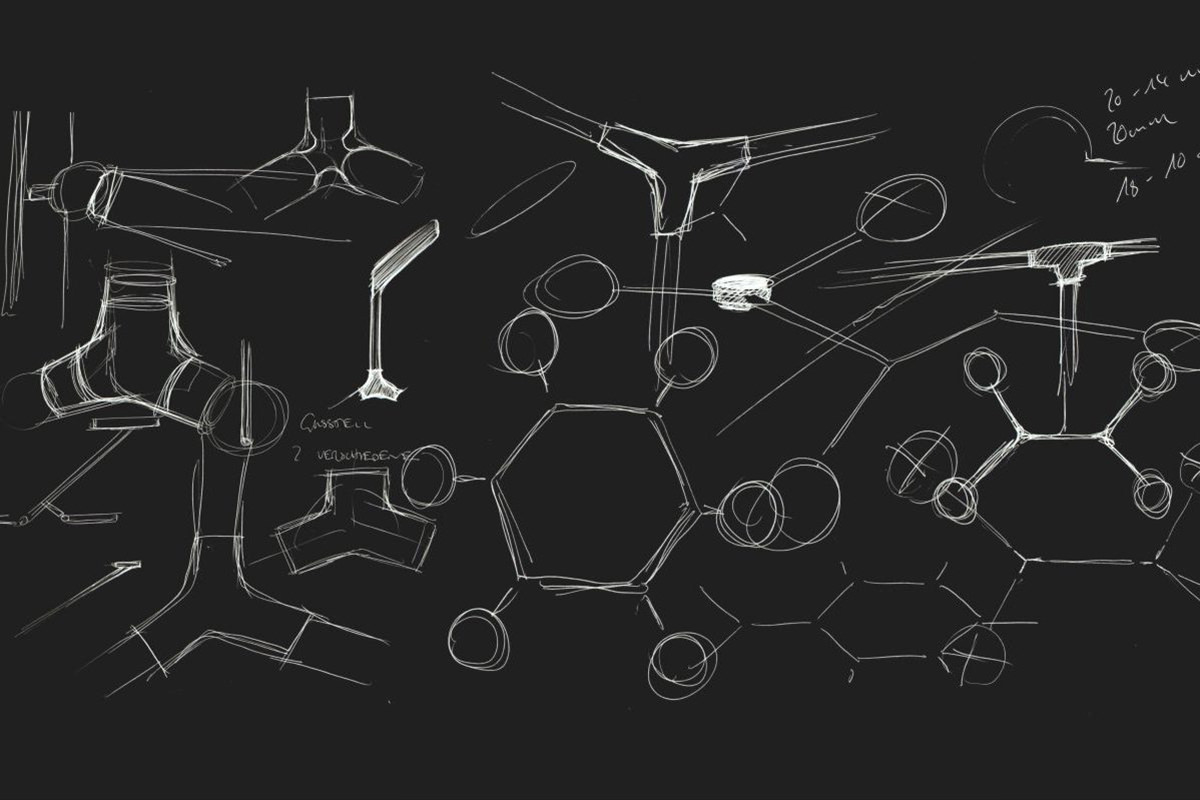

Michael Schmidt and code2design are an interdisciplinary design studio for product innovations and industrial design. Our holistic design approach enables us to design and develop innovative products with personality. Products that tell a story and inspire people. This is how brand identity is created. For more than 25 years.

Awarded Design Excellence – Iconic Design That Inspires People

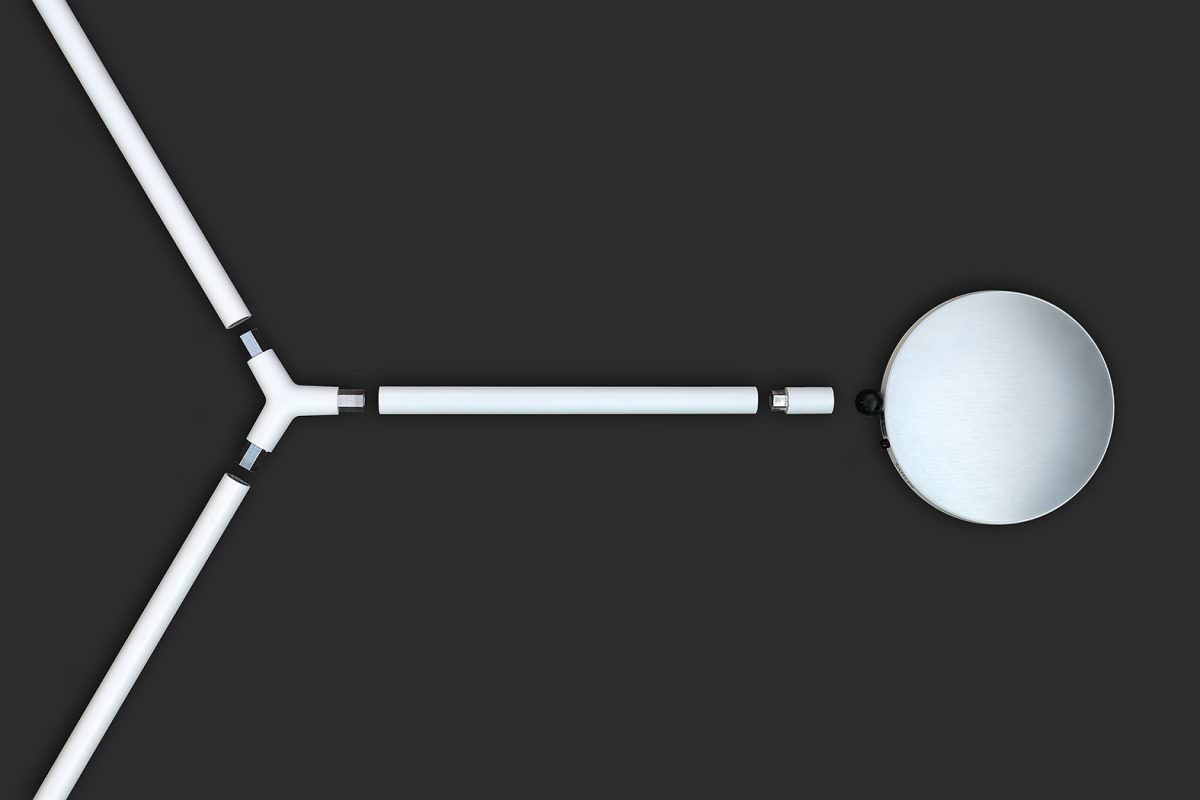

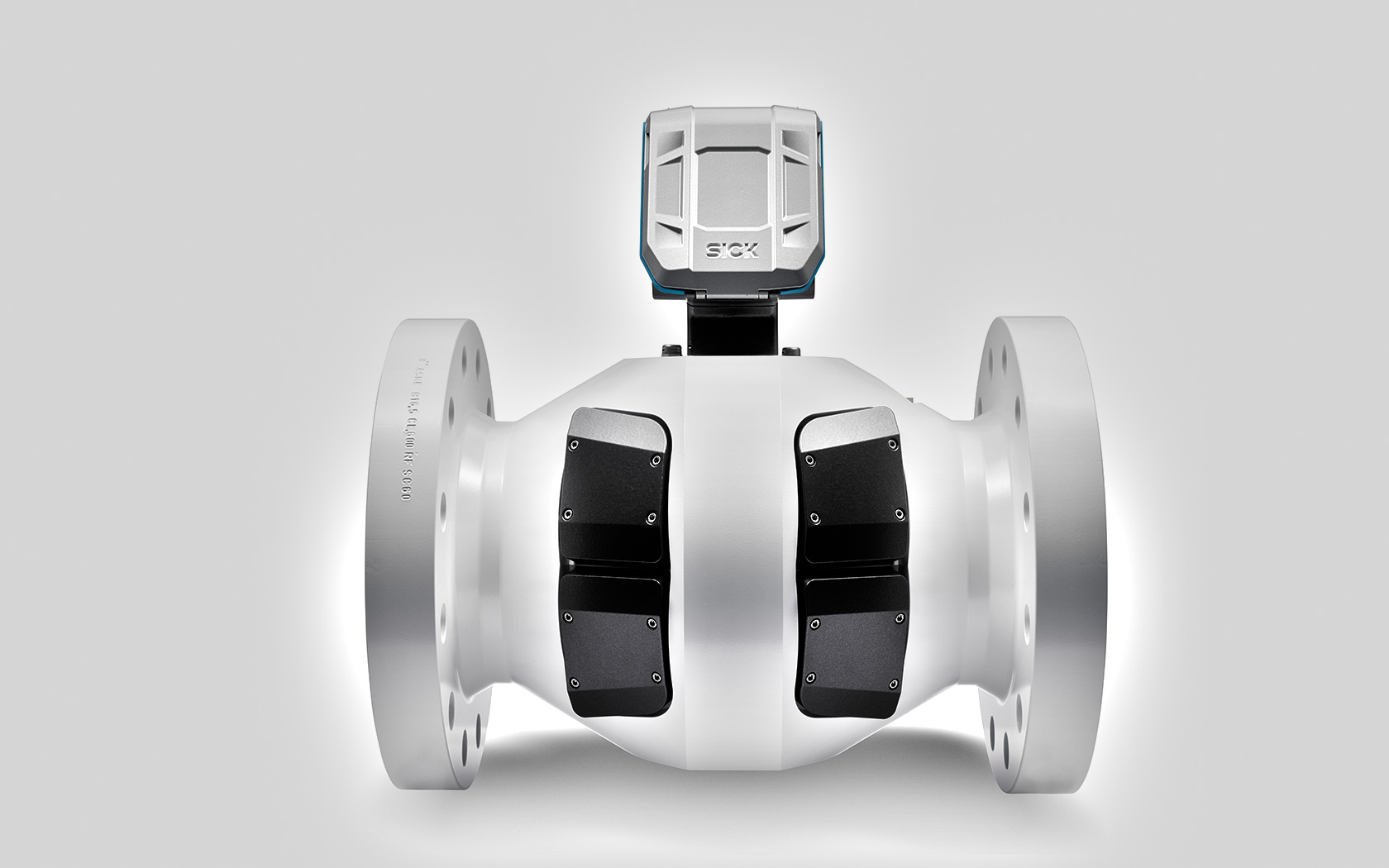

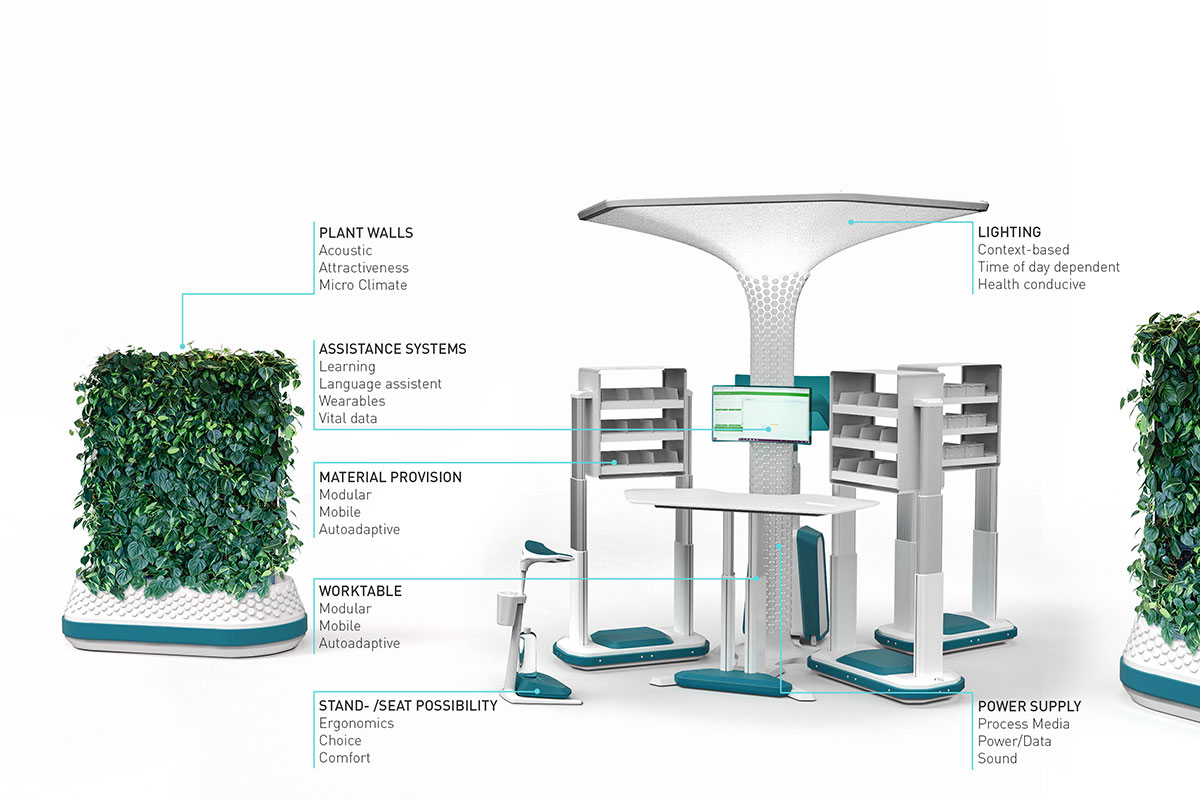

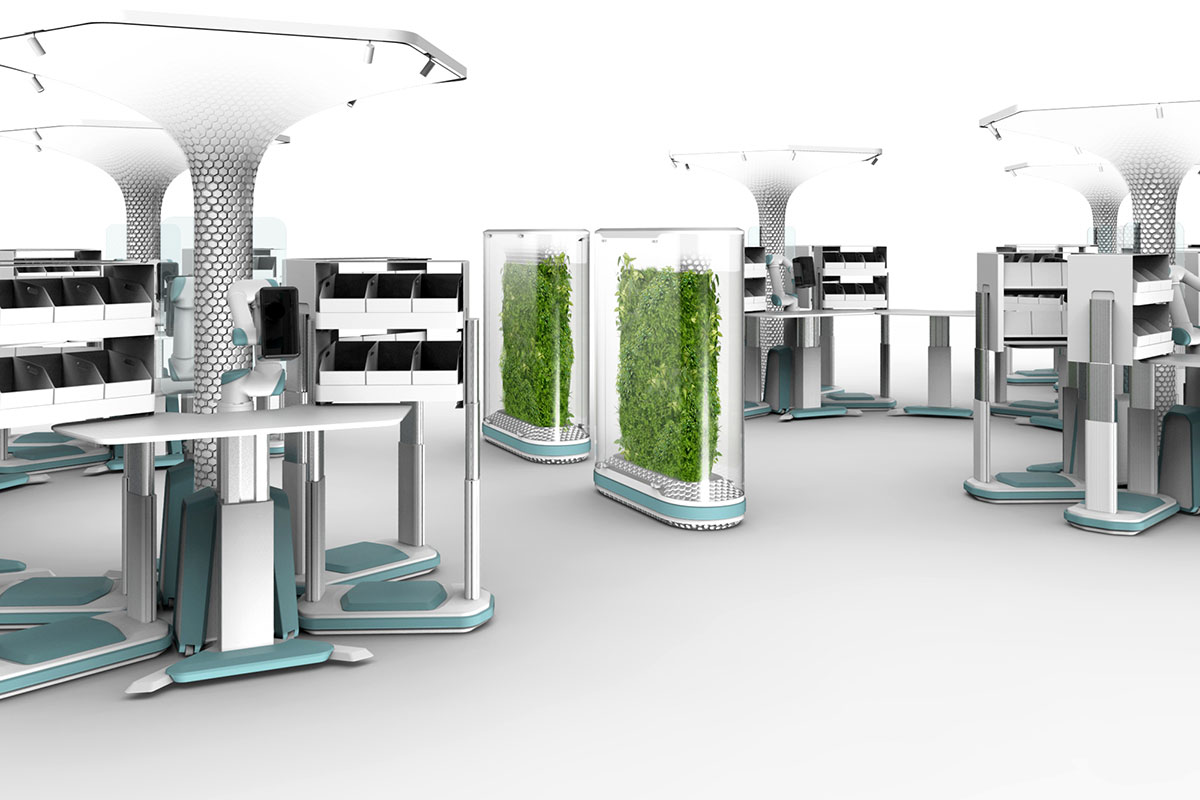

We create products that bring brand identity to life and position companies sustainably in the market. With over 75 international design awards, our product design stands for innovation, outstanding user experience, and strategic market success.

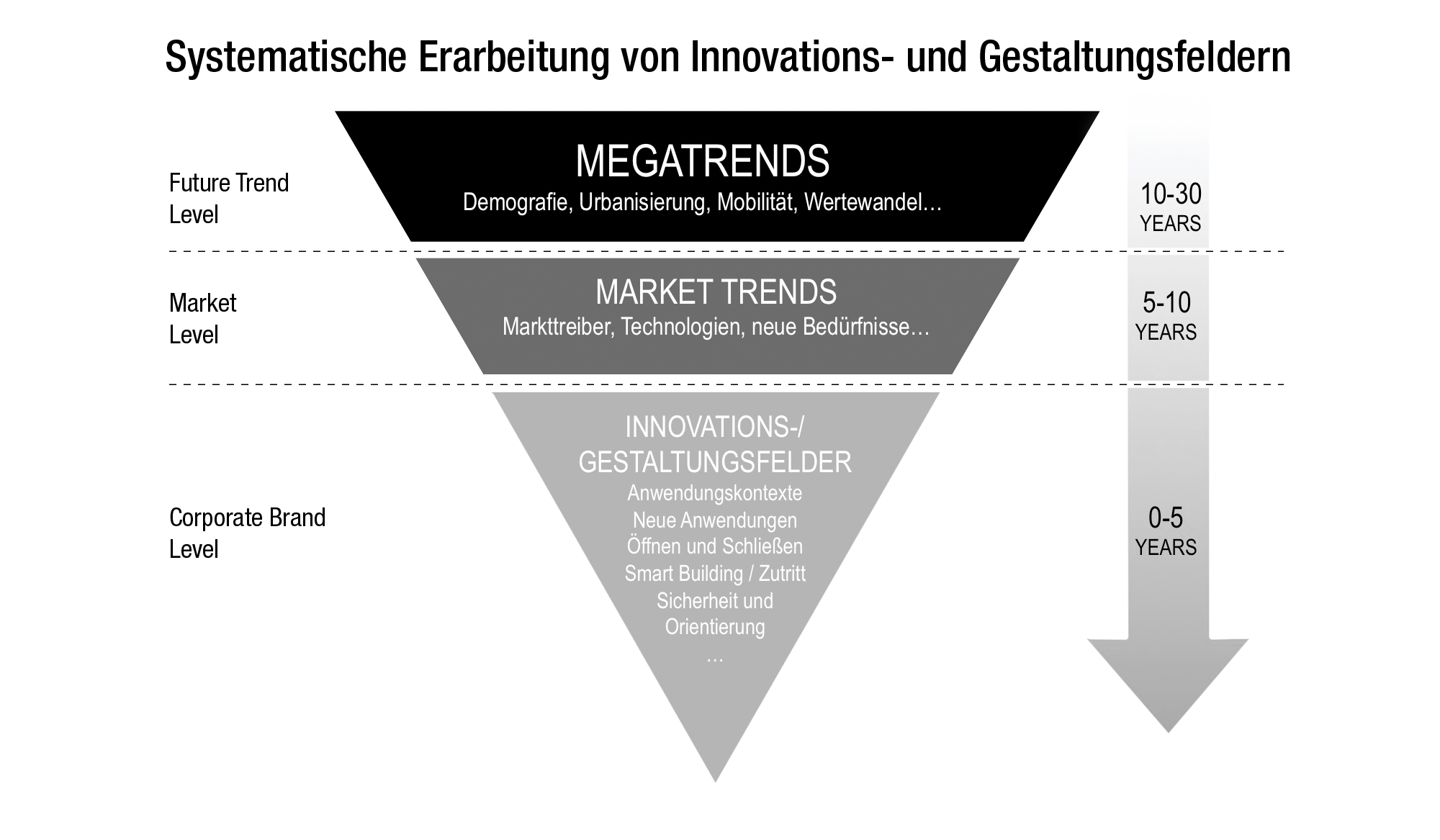

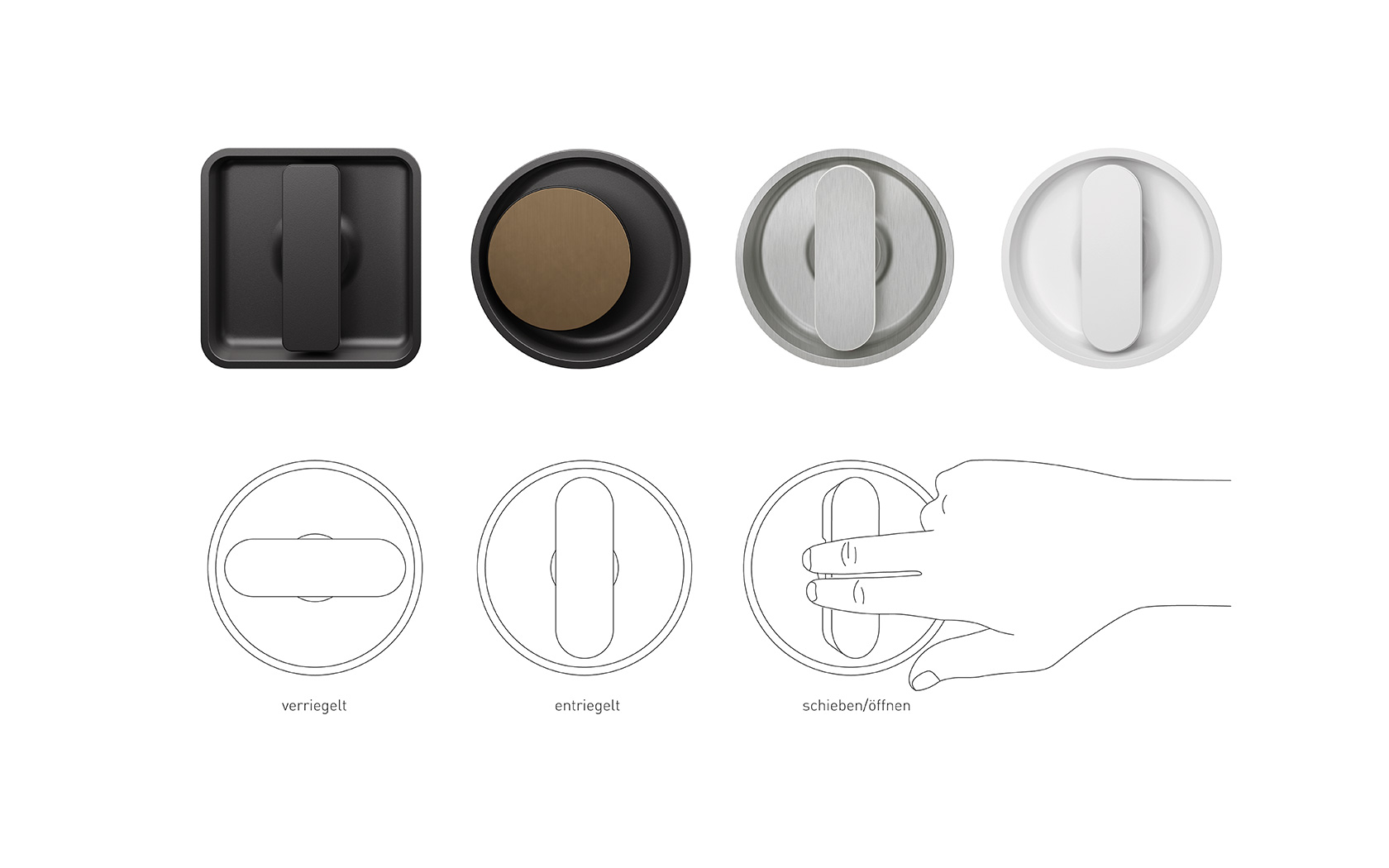

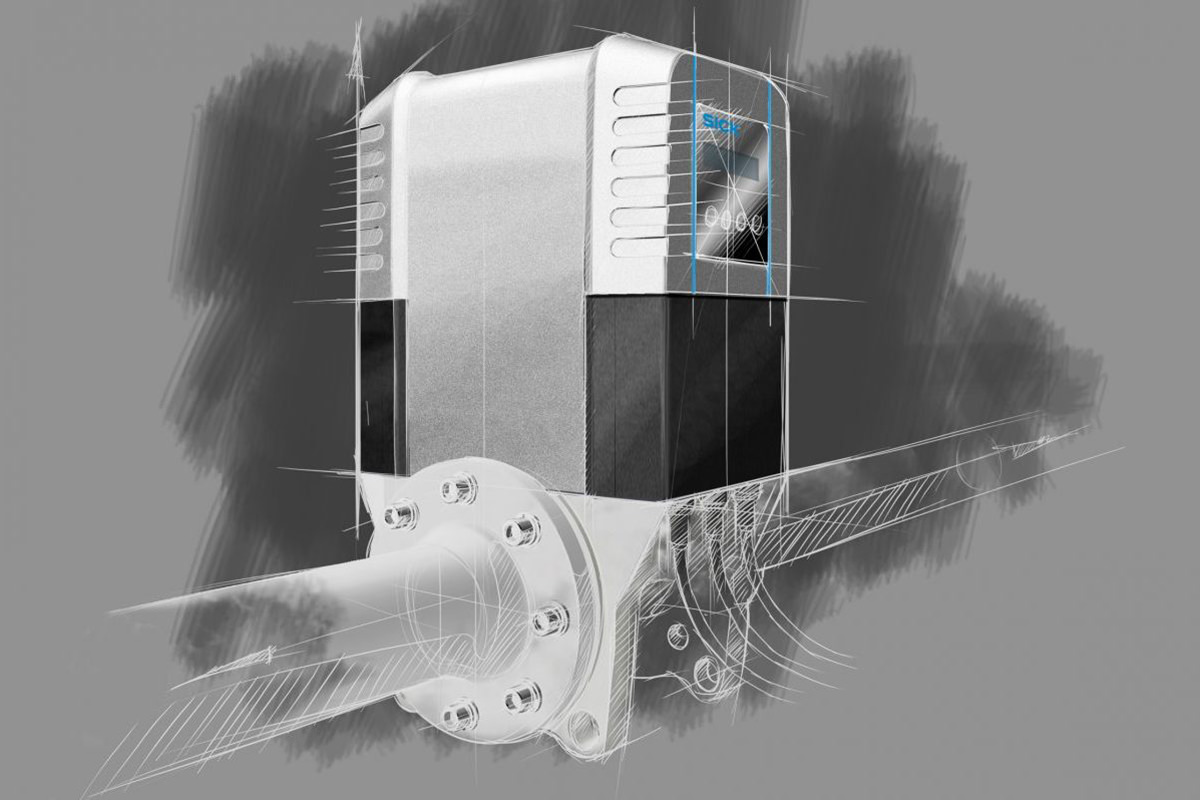

Our holistic 360° design approach combines deep user understanding and market expertise with technical know-how to create products with character and high recognition value. This results in products that not only excel functionally but also tell stories and fascinate people.

Design that inspires people, strengthens brands, and creates lasting value – for over 25 years